- BIS Certification Guide: This is a mandatory license required to manufacture or import goods like steel and electronics in India.

- ISI Mark (Scheme I): Requires a physical Factory Audit + Lab Testing (e.g., for Steel, Cement, Appliances).

- CRS (Scheme II): Requires Lab Testing + Online Registration only (e.g., for Electronics, Solar, Batteries).

- 2026 Regulatory Alert: Significant changes have occurred. Mandatory QCOs for several Chemicals & Textiles were withdrawn in late 2025, while strict new deadlines for Furniture (Feb 2026) and Electricals are now active.

- Who Can Apply? The license is granted only to the Factory (Manufacturer), whether in India or abroad. Importers cannot hold the license but must ensure their suppliers are certified.

- The Risk: Non-compliant goods face immediate Customs seizure, stop-sale orders, and heavy fines under the BIS Act.

Introduction

India presents a tremendous opportunity for manufacturers and importers; however, access to this opportunity is dependent on compliance.

If you intend to sell products such as: heavy machinery, steel, chemicals and electronics in India, you will likely be interacting with the Bureau of Indian Standards (BIS). It is important to note that BIS certification is not just a "quality" mark similar to ISO 9001 certification. ISO provides you with a certification indicating the quality of your processes, whereas BIS certification indicates that your product has met required standards.

As per the BIS Act 2016, the government of India has completely changed its position regarding product regulation and through the increased number of Quality Control (QC) Orders (QCOs), has made certification of hundreds of different categories of products mandatory in order to eliminate low quality imported products and to ensure public safety.

Therefore, it doesn't matter if you are a local manufacturer in Gujarat or a foreign manufacturer located in Germany. The requirements will be the same for both locations—no license, no sale.

In order to successfully navigate this environment, it is very important to have a complete understanding of the differences between Scheme I (ISI Mark) and Scheme II (CRS) of BIS certification as it pertains to your products by having knowledge of the Indian Standards (IS codes). A misinterpretation here can lead to rejected applications or seized containers at customs.

This guide serves as your technical roadmap. We will break down the regulatory framework, the specific testing protocols, and the mandatory audit requirements you need to fulfill to legally place your products in the Indian market in 2025.

At Silvereye Certifications, we specialize in interpreting these regulations. We help you translate complex government mandates into a clear, actionable path to compliance.

What is BIS Certification Guide and Why is it Mandatory?

The Bureau of Indian Standards (BIS) is the National Standards Body of India. Think of them as the gatekeepers of quality.

While their core purpose is to ensure Safety, Quality, and Trust (protecting the final consumer from exploding chargers or substandard cement), the business reality is legal compliance.

The "Mandatory" Factor (QCOs)

Historically, BIS certification was voluntary for many products. You got it if you wanted a "badge of quality."

That has changed. The Government of India now issues Quality Control Orders (QCOs) regularly. Once a QCO is issued for your product (e.g., Copper Products, Footwear, or Viscose Staple Fibre), obtaining a license becomes illegal to avoid.

Note: Compliance is not just for the manufacturer. If you are a trader or warehouse owner stocking non-compliant goods, you are also liable.

Who Needs BIS Certification?

The responsibility to obtain the license always lies with the manufacturer, but the need affects the entire supply chain.

1. Domestic Manufacturers

If your factory is in India and you make goods listed under mandatory certification (like structural steel or electric irons), you must have the license before you start commercial production.

2. Foreign Manufacturers (FMCS)

If you manufacture outside India but want to export here, you need the FMCS (Foreign Manufacturers Certification Scheme).

- Crucial Detail: The license is granted to the factory location, not to your Indian importer. If you have three factories in China and Vietnam, you might need three separate licenses.

3. Importers & Traders

Importers cannot apply for the license themselves. However, you are the ones who face the heat at Indian Customs. You must ensure your overseas supplier holds a valid BIS license before you ship a single container.

Key Benefits of BIS Certification

Obtaining a BIS license isn't just about following the rules—it’s a strategic advantage for your business in 2025.

- Total Market Access: It is the only way to legally sell products listed under Quality Control Orders (QCOs) in India. Without it, your goods will be blocked at Customs or seized from the market.

- Unlock Government Contracts: You cannot bid for lucrative tenders (Railways, Defence, Smart Cities) without a valid BIS license number. It is a mandatory pre-qualification.

- Instant Consumer Trust: The ISI Mark is one of India's most trusted symbols. It instantly signals safety and durability to customers, allowing you to compete against established brands.

- Eliminate Cheap Competition: Mandatory certification wipes out low-quality "grey market" imports that cannot pass lab tests, leaving more market share for compliant manufacturers like you.

- Command Higher Margins: Certified products carry a badge of quality. Customers—both B2B and B2C—are willing to pay a premium for the assurance that the product won't fail or cause harm.

Understanding the Different Types of BIS Certification Schemes

One of the biggest sources of confusion for manufacturers is realizing that "BIS Certification" isn't a single process. The Bureau of Indian Standards operates under the BIS (Conformity Assessment) Regulations, 2018, which outlines several schemes.

However, for 99% of businesses (manufacturers and importers), only two schemes matter. Knowing which one your product falls under is critical because it dictates your budget, timeline, and whether or not a government officer visits your factory.

1. Scheme I: The ISI Mark (Product Certification Scheme)

This is the oldest and most recognized scheme. When people say "BIS Hallmark" or "ISI Mark," this is usually what they mean. It is generally reserved for products that have a direct impact on public safety, health, or national infrastructure.

- Who is it for? Manufacturers of "high-risk" or "critical" goods.

- Key Products: Cement, Structural Steel, Chemicals (like Caustic Soda), Bottled Water, Tyres, Electrical Appliances (Heaters, Irons), and Toys.

- The Process (The "Hard" Path):

- Factory Audit: Mandatory. A BIS officer will visit your factory (in India or abroad) to assess your manufacturing infrastructure.

- In-House Lab: You must have a fully equipped testing lab inside your factory.

- Testing: Samples are drawn during the audit and sent to a third-party lab.

- The Output: You get a license to use the standard ISI Mark on your products.

2. Scheme II: Compulsory Registration Scheme (CRS)

Introduced in 2012 by the Ministry of Electronics and Information Technology (MeitY), this scheme was designed for the fast-moving tech sector. It is a simplified "Self-Declaration" model.

- Who is it for? Manufacturers of electronics, IT goods, and solar components.

- Key Products: Laptops, Mobile Phones, Power Adapters, Smart Watches, LED Lights, Solar Inverters, Batteries.

- The Process (The "Fast" Path):

- No Factory Audit: In most cases, BIS does not visit the factory.

- Testing First: You send samples to a BIS-recognized lab in India.

- Registration: Once you have the test report, you apply online. BIS reviews the documents and grants the registration.

- The Output: You get a Registration Number (R-Number) which must be printed on the product and packaging (e.g., R-12345678).

3. FMCS (Foreign Manufacturers Certification Scheme)

While legally this falls under Scheme I or II, in the business world, it is treated as a separate category because of the complexity.

- What is it? This is the route for foreign factories (located outside India) to get the ISI Mark.

- The Challenge: It requires a VISA for the auditor, travel arrangements, and a Performance Bank Guarantee (PBG) of USD 10,000. It also requires the appointment of an Authorized Indian Representative (AIR).

Eligibility Criteria: Who Can Apply?

Before we talk about documents, we need to clear up the biggest misconception in the industry: Who actually gets the license?

1. The "Manufacturer Only" Rule

The BIS license is site-specific and manufacturer-specific.

- Eligible: The factory that physically produces the goods. Whether you are in Mumbai, Munich, or Manila, the license is granted to the manufacturing address.

- Not Eligible: Importers, Traders, Wholesalers, and Retailers. You cannot apply for a license on behalf of a supplier. You can only import from a licensed supplier.

2. Foreign Manufacturers (FMCS)

If your factory is located outside India, you are eligible to apply under the Foreign Manufacturers Certification Scheme (FMCS).

- Condition: You must nominate an Authorized Indian Representative (AIR). This person/entity must be a resident of India and takes legal responsibility for your compliance.

3. Brand Owners (The Grey Area)

If you own a brand (e.g., "TechPro Speakers") but outsource manufacturing to a generic factory (OEM), the factory must apply for the license, not you. However, the factory can list your brand name on the license so you can market the product.

Mandatory Requirements for BIS Certification

BIS compliance isn't just about filling out a form; it is about proving you have a robust quality management system. Here is the checklist you must satisfy before applying.

1. Physical Manufacturing Setup

You cannot get a license for a "virtual" factory or a warehouse.

- Requirement: You must have all the machinery required to manufacture the product at the address listed in the application.

- Verification: For ISI (Scheme I), the auditor will physically verify that the machinery is present and operational.

2. In-House Testing Laboratory (Critical for ISI)

This is the most challenging requirement for Scheme I (ISI Mark).

- Requirement: You must have a fully equipped testing lab inside your factory premises.

- Scope: The lab must be able to perform the tests outlined in the specific Indian Standard (IS Code).

- Calibration: All testing equipment must be calibrated.

- Note: For CRS (Electronics/IT), an in-house lab is generally not required; testing is done at independent BIS-recognized labs.

3. Qualified Quality Control (QC) Personnel

Machinery isn't enough; you need competence.

- Requirement: You must employ a dedicated Quality Control In-charge (Chemist/Engineer).

- The Test: During the factory audit, the BIS officer will ask your QC person to test a sample live. If they fail to demonstrate the correct testing method, the application will be rejected.

4. Legal & Technical Documentation

You must have the following documents ready and translated into English (or Hindi):

- Proof of Address: Factory license or property deed.

- Process Flowchart: A diagram showing the manufacturing process from raw material to finished good.

- List of Raw Materials: Proof that you are using high-quality inputs (some raw materials may also need their own BIS certification).

- Layout Plan: A map of the factory floor and laboratory.

5. Product Samples

- Requirement: You must have finished goods ready to be tested.

- The Rule: The sample sent to the lab must be from the same production line as your regular stock. Hand-made "golden samples" often fail when compared to mass-produced reality during audits.

The Step-by-Step Certification Process

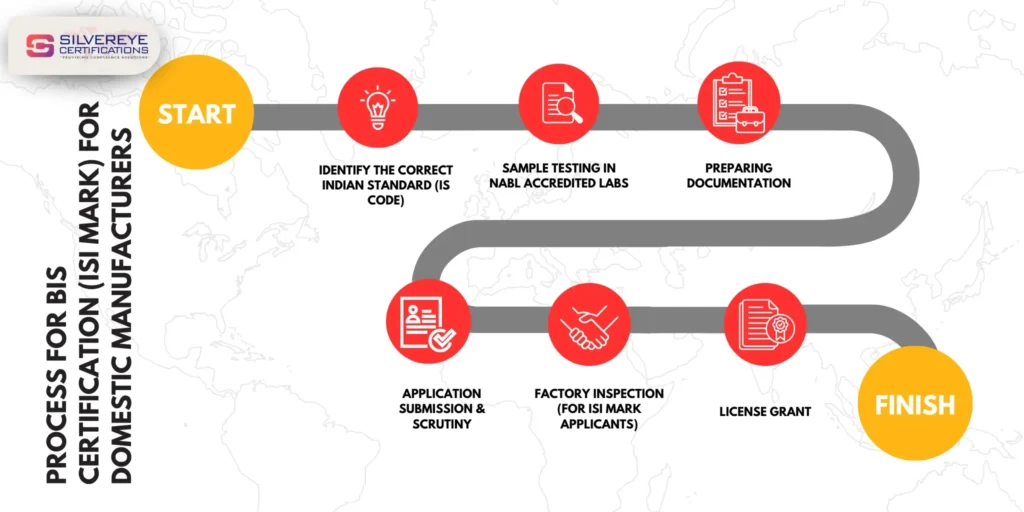

Whether you are applying for ISI or CRS, the logic is similar, but the intensity differs.

Step 1: Identify the Standard (IS Number)

Don't guess. "Steel" covers dozens of codes. Are you making Stainless Steel Pipe (IS 6911) or Mild Steel Wire (IS 280)? Getting this wrong means your application gets rejected instantly.

Step 2: Documentation & Application

You submit your business docs (more on this below) via the Manak Online portal.

- For Foreigners: This is where you nominate your Authorized Indian Representative (AIR).

Step 3: Sample Submission

You must send product samples to a BIS-Recognized Lab in India.

- Expert Tip: Do not just pick a sample off the line. Pre-test it. If your sample fails in the official lab, you don't get a second chance; you have to restart the whole process and pay the fees again.

Step 4: The Factory Audit (ISI Only)

For ISI products, a BIS officer flies to your factory (even abroad). They will:

- Verify your manufacturing machinery.

- Check your quality control staff's competency.

- Witness a live test in your factory lab.

- Seal a sample to take back for independent testing.

Step 5: Grant of License (CML Number)

Once the test reports pass and the audit is cleared, you pay the license fee. You are awarded a CM/L (License) number or an R-Number (for CRS), which you must print on your product.

Essential Documents Checklist

Missing documents is the #1 reason for delays. Keep this "Quick Scan" list ready:

- Business Proof: Incorporation certificate, MOA/AOA, or MSME certificate.

- Factory Details: Complete address proof and a Layout Plan of the factory floor.

- Process Flow: A flowchart showing how you make the product (from raw material to packaging).

- Machinery List: List of all manufacturing equipment.

- Testing Equipment List: (Critical for ISI) List of all calibration-valid instruments in your lab.

- AIR Nomination: For foreign clients, a formal letter appointing your Indian representative.

Need help with the AIR? At Silvereye Certifications, we often guide foreign brands on how to structure their AIR representation to ensure legal compliance.

Critical QCO Updates & Deadlines (2026 Outlook)

The regulatory landscape has shifted dramatically in late 2025. The Government of India has adopted a more targeted approach, enforcing strict norms on consumer safety products (Furniture, Electricals) while offering huge relief to the chemical and textile sectors to boost ease of doing business.

Here is the verified status as of December 2025:

1. MAJOR RELIEF: Withdrawn QCOs (Deregulation)

In a significant move to support the industry, the Ministry of Chemicals & Fertilizers and Ministry of Textiles have rescinded (cancelled) the Quality Control Orders for the following products.

- What this means: You do NOT need a mandatory BIS license to manufacture or import these specific goods anymore (though voluntary certification is still allowed).

| Sector | Product (QCO Withdrawn) | Status |

| Chemicals | Pyridine, Beta Picoline, Sodium Tripolyphosphate | Withdrawn (Nov 2025) |

| Chemicals | H-Acid, K-Acid, Vinyl Sulphone | Withdrawn (Nov 2025) |

| Chemicals | Toluene, p-Xylene, Methyl/Ethyl Acrylate | Withdrawn (Nov 2025) |

| Textiles | Viscose Staple Fibre (VSF) | Withdrawn (Nov 2025) |

| Textiles | Polyester Spun Yarn (PSY) | Withdrawn (Late 2025) |

Expert Note: While legal mandates have dropped, many large Indian buyers (B2B) still prefer BIS-certified suppliers for quality assurance. Don't discard your quality manuals just yet!

2. NEW MANDATES: Active Deadlines for 2026

While chemicals got a break, Consumer Goods and Industrial Safety norms are tightening. If you manufacture the following, your deadline is fast approaching.

| Product Category | Specific Products | Deadline / Status |

| Furniture | Work Chairs, Tables, Beds, Storage Units | Feb/March 2026 |

| Electricals | Ceiling Fans, Water Heaters, Kitchen Appliances | March 19, 2026 (Extended) |

| Plastic Moulding | Polypropylene (PP) Materials | April 24, 2026 |

| Aluminium | Aluminium Alloy Products (Pots, Pans, Foil) | Jan 2026 (Small Ent) / April 2026 (Micro) |

| Machinery | Industrial Safety Machinery ("Scheme X") | Phased Implementation 2026 |

The Furniture QCO is a game-changer. It covers finished goods like office chairs and beds. If you import furniture from China or Vietnam, or manufacture in India, you must have the ISI mark by February 2026. Customs will start checking strictly from day one.

How much does BIS certification cost in India?

1. Scheme I: ISI Mark (For Domestic Manufacturers)

Applicable for: Steel, Cement, Chemicals, Toys, Footwear, etc.

| Cost Component | Estimated Amount (INR) | When to Pay? |

| Application Fee | ₹1,000 | At the time of application submission. |

| Audit Fee | ₹7,000 per man-day | Paid before the factory audit. (Usually 1-2 days). |

| Sample Testing Fee | ₹10,000 – ₹2,00,000+ | Paid to the Lab. Varies heavily by product (e.g., Water is cheap; Steel is expensive). |

| License Fee | ₹1,000 | Annual fee paid after the grant of license. |

| Minimum Marking Fee | ₹25,000 – ₹55,000 | Paid annually. Calculated based on your production volume (Medium/Large scale pays more). |

2. Scheme II: CRS (Compulsory Registration Scheme)

Applicable for: Electronics, IT Goods, Solar, Battery, etc.

| Cost Component | Estimated Amount (INR) | When to Pay? |

| Application Fee | ₹1,000 | At the time of application. |

| Processing Fee | ₹50,000 | One-time fee for the grant of registration. |

| Sample Testing Fee | ₹15,000 – ₹80,000 | Paid to the Lab. Varies by product (e.g., Adapters vs. Large LED Displays). |

| Professional Fee | Varies | If you hire a consultant (Silvereye) to handle the testing and paperwork. |

| Renewal Fee | ₹25,000 | Paid every 2 years to renew the license. |

3. FMCS (Foreign Manufacturers Certification Scheme)

Applicable for: Factories located OUTSIDE India (China, Vietnam, Europe, etc.)

| Cost Component | Estimated Amount | Notes |

| Application Fee | ₹1,000 | Non-refundable. |

| Audit Fee | ₹7,000 per man-day | Usually 2 auditor days. |

| License Fee | ₹1,000 | Annual fee. |

| AIR Service Fee | Varies | Fee paid to your Authorized Indian Representative (AIR) annually. |

| Testing Fee | ₹20,000 – ₹3,00,000 | Paid to the Indian Lab. |

Validity & Renewal of BIS Certification

The government doesn't grant you a "lifetime" license. You must renew it periodically to prove you are still maintaining quality.

| Feature | Scheme I: ISI Mark (Steel, Cement, Toys) | Scheme II: CRS (Electronics, IT) | FMCS (Foreign Mfrs) |

| Initial Validity | 1 Year (Standard) | 2 Years | 1 to 2 Years |

| Renewal Period | Can be renewed for 1 to 5 Years at a time. | Can be renewed for 2 to 5 Years at a time. | Can be renewed for 1 to 5 Years at a time. |

| When to Apply? | Apply 3 months before expiration. | Apply 3 months before expiration. | Apply 3 months before expiration. |

| Renewal Fee | ₹1,000 (Application) + Annual Marking Fees (Based on production). | ₹25,000 (for 2 years) or ₹50,000 (for 5 years). | ₹1,000 + Annual Marking Fees + USD 10,000 (Bank Guarantee verification). |

| Late Fee? | ₹5,000 (if applied after expiry date but within 90 days). | ₹5,000 + (if applied after expiry date). | ₹5,000 (Strict enforcement). |

| Is Retesting Needed? | No, unless the Standard (IS Code) has changed. | No, unless the Standard (IS Code) has changed. | No, unless significant changes in product/standard. |

Consequences of Non-Compliance

Why hire an expert like Silvereye Certifications? Because the cost of getting it wrong is massive.

- Customs Seizure: If your shipment arrives without a valid BIS registration number on the packaging, Customs will hold it. You will pay demurrage (storage) charges every day until you eventually have to destroy the goods or re-export them.

- Stop-Sale Orders: BIS enforcement teams conduct market raids. If they find non-compliant toys or steel in your warehouse, they issue a "Stop Sale" order immediately.

- Legal Action: Misusing the ISI mark (printing it without a license) is a criminal offense carrying hefty fines and potential imprisonment.

Conclusion: Don't Let Compliance Stop Your Sales

BIS Certification is complex, technical, and strict—but it is the key to unlocking the massive Indian market. Whether you are launching the next big smartphone or supplying steel for infrastructure, the "Standard Mark" is your passport.

Don't risk rejection due to a wrong IS code or a failed sample.

Ready to get certified?

Let Silvereye Certifications handle the paperwork, the lab coordination, and the BIS liaison while you focus on your business.

[Contact Silvereye Certifications for a Free Assessment]

QCO norms are tightening in 2026. Don't let a missing document halt your import. Book a Free Compliance Audit with Silvereye Today.

Frequently Asked Questions

Is BIS mandatory for everything?

No, only for products listed under Quality Control Orders (QCOs) (e.g., steel, toys, electronics, chemicals). If it's on the list, selling without a license is illegal.

Can an importer get the license?

No. The license belongs to the factory (manufacturer) only. Importers cannot apply; they can only represent the foreign factory.

What’s the difference: ISI vs. CRS?

ISI (Scheme I): For safety/industrial goods (Steel, Cement). Requires a Factory Audit.

CRS (Scheme II): For electronics (IT, Solar). Requires Lab Testing only (usually no audit).

How long does it take?

CRS: 30–60 days.

ISI (Indian Factory): 3–4 months.

FMCS (Foreign Factory): 4–6 months.

Do I need a lab in my factory?

ISI: Yes. A fully equipped in-house lab is mandatory.

CRS: No. You generally don't need one.

Can I sell first and certify later?

No. You need the license number (CML/R-Number) printed on the product before it clears Customs or enters the market.

Is one license valid for all my factories?

No. Licenses are location-specific. Separate factories = Separate licenses.

What if my sample fails the test?

Your application is rejected. You lose your fees and must restart the process from scratch. Pre-testing is crucial.

Is the license valid forever?

No. It is valid for 1–2 years initially. You must pay renewal fees to keep it active or it gets cancelled.

What is an AIR?

Foreign manufacturers must appoint an Authorized Indian Representative (AIR) located in India to take legal responsibility for the compliance.