- New BIS Standard For Incense Stick Under IS 19412:2025 the first dedicated safety standard for incense sticks, banning toxic chemicals like Alethrin and Benzyl Cyanide.

- Impact on Manufacturers: Compliance requires strict raw material sourcing, lab testing for banned substances, and new labeling protocols to earn the BIS Standard Mark.

- Market Shift: While currently voluntary, early adoption offers a massive competitive edge in the ₹8,000 Cr domestic market and protects against future Quality Control Orders (QCOs).

Introduction – Why a New BIS Standard for Incense Sticks?

For decades, the sweet aroma of agarbattis has been synonymous with Indian spirituality. Every morning, millions of households from Kashmir to Kanyakumari light a stick, believing it purifies the air. But for manufacturers and industry insiders, there has been an uncomfortable truth lingering in that smoke: What exactly are we burning?

Until now, the incense industry operated largely on tradition and voluntary norms. However, with the massive rise in "mosquito repellent" agarbattis and chemically dipped sticks, the line between spiritual aroma and chemical hazard blurred. This led to the landmark release of IS 19412:2025 on National Consumer Day 2025.

If you are a manufacturer or brand owner, this isn't just another bureaucratic circular. It is a fundamental shift in how India defines "safe" incense. It separates the high-quality, export-ready products from the low-grade, toxic sticks that flood the local market.

Growing Concerns Around Incense Stick Safety & Indoor Air Quality

We have all seen the headlines. Reports from bodies like CSIR-IITR have flagged that burning certain low-quality sticks releases Volatile Organic Compounds (VOCs) and Particulate Matter (PM 2.5) higher than cigarette smoke. When you burn a stick coated in unverified synthetic oils or "dipping chemicals" inside a closed puja room, you aren't just inhaling fragrance; you might be inhaling known carcinogens.

Launch of IS 19412:2025 on National Consumer Day 2025

On December 24, 2025, Union Minister Pralhad Joshi officially unveiled IS 19412:2025. This timing was deliberate. By launching it on National Consumer Day, the government sent a clear message: Incense sticks are consumer products, not just religious items, and they must be safe.

Objectives of the New Standard – Safety, Quality & Environmental Protection

The goal is threefold:

- Health: Eliminate "hidden" pesticides often used to boost burning or repellency.

- Quality: Standardize the burning duration and fragrance retention.

- Environment: Reduce the release of toxic ash and fumes into our homes.

Overview of IS 19412:2025 – Incense Sticks (Agarbatti)

What IS 19412:2025 Covers and Why It Matters

Think of IS 19412:2025 as the "Gold Standard" for the agarbatti industry. It is a comprehensive document that dictates everything from the bamboo splint quality to the chemical composition of the final smoke. It provides the technical specifications required to obtain a BIS Certification or Agarbatti license.

Key Takeaway: If your product carries the IS 19412 mark, it tells the consumer, "This stick is safe to breathe."

Key Stakeholders Involved in Drafting the Standard

This wasn't written in a vacuum. The BIS Fragrance and Flavour Sectional Committee (PCD 18) collaborated with heavyweights including:

- CSIR Labs: CIMAP (Medicinal Plants), IITR (Toxicology), and CFTRI (Food Tech).

- FFDC Kannauj: The Fragrance and Flavour Development Centre.

- AIAMA: All India Agarbatti Manufacturers Association.

Difference Between Earlier Provisions (e.g., IS 13582) and the New Dedicated Standard

Previously, we relied on generic standards like IS 13582 (which covered "incense raw materials" broadly) or specific standards for "mosquito coils." There was no dedicated holistic standard for the finished agarbatti product. IS 19412:2025 fills that gap by treating the agarbatti as a complete system—stick, paste, and perfume combined.

Scope & Classification of Incense Sticks Under the New Standard

Types of Agarbattis Covered

The standard acknowledges the diversity of Indian manufacturing. It explicitly classifies products into three categories:

- Machine-Made: High-volume, uniform sticks (usually dipped).

- Hand-Made: The traditional rolling method, often used by cottage industries.

- Traditional Masala Incense Sticks: Dough-based sticks (Flora/Durbar style) where the fragrance is kneaded into the paste, not dipped.

Product Forms and Variants Likely to Be Included / Excluded

While the primary focus is on the bamboo-cored stick, the principles of chemical safety (banned substances) are setting a precedent for related formats like Dhoop sticks, Cones, and Logs. If you manufacture these variants, expect similar scrutiny soon, as the raw material guidelines often overlap.

Applicability to Domestic Market vs. Export-Oriented Units

Currently, this is a voluntary standard for the domestic market. However, for exporters, this is practically mandatory. European and US buyers are already demanding "REACH compliance" or "Non-Toxic" certificates. IS 19412:2025 gives you an Indian-government-backed document to prove that safety.

Core Technical Requirements of IS 19412:2025

Raw Material Requirements

You can no longer use "whatever burns." The standard specifies:

- Base Stick: Must be dry, pest-free bamboo.

- Binders (Jigat/Machilus): Must be natural and free from synthetic adulterants that produce black smoke.

- Fragrance: Must adhere to IFRA (International Fragrance Association) safety norms.

Burning Performance

Your stick cannot fizzle out halfway. The standard tests for:

- Ignition: Does it light easily?

- Burning Rate: Is it consistent? A 9-inch stick shouldn't burn out in 10 minutes; it needs a standardized burn time (e.g., 30-45 mins depending on thickness).

- Ash Behaviour: The ash should not fall hot (causing burns) or fly away easily (creating mess).

Fragrance Performance

It’s not enough to smell good in the box. The aroma must remain consistent during burning (burning note) and must have a specified retention period (shelf life).

Chemical Safety Parameters

This is the most critical section. The standard sets strict limits on Carbon Monoxide (CO) and Nitrogen Oxides (NOx) emissions during combustion.

Prohibited & Restricted Substances in Incense Sticks

This section is where many existing formulations will fail. To ensure safety, BIS has explicitly banned specific chemicals often found in "mosquito repellent" agarbattis or cheap synthetic fragrances.

Banned Insecticidal Chemicals in Agarbattis

If you are marketing your product as a "Mosquito Agarbatti" without a CIB (Central Insecticides Board) license, you are already non-compliant. But even for "spiritual" sticks, traces of these are now strictly prohibited:

- Alethrin

- Permethrin

- Cypermethrin

- Deltamethrin

- Fipronil

Prohibited Synthetic Fragrance Intermediates

Certain chemical intermediates used to create cheap, strong smells are now off the table due to toxicity:

- Benzyl Cyanide

- Ethyl Acrylate

- Diphenylamine

Rationale – Human Health Risks

Why the ban? When burned, substances like Alethrin can cause respiratory distress and neurological issues if inhaled in a closed room daily. Ethyl Acrylate is a potential carcinogen. The logic is simple: A product used for prayer shouldn't act like a slow poison.

Benefits of BIS Certification for Incense Manufacturers

Why should you invest time and money into getting certified if it's currently voluntary? The answer lies in market differentiation and risk management. Here is how a certified brand compares to a non-certified one:

| Benefit Category | Non-Certified Brand (Generic) | BIS Certified Brand (IS 19412:2025) |

| Consumer Trust | Relies on generic claims like "Natural" which consumers are increasingly skeptical of. | Instant Credibility: The ISI Mark serves as a government-backed guarantee of safety and quality. |

| Price Command | Locked in a price war. Difficult to justify premium pricing (₹50+). | Premium Pricing: Validates "Chemical-Free" claims, allowing you to charge higher margins for a verified safe product. |

| Retail Access | Restricted to general trade (kirana stores) and loose markets. | Modern Trade Entry: Essential for shelf space in supermarkets (Reliance, DMart) and quick-commerce platforms (Blinkit, Zepto). |

| Export Potential | Struggles with strict EU/US safety norms; often requires expensive private testing per shipment. | Global Acceptance: IS 19412 aligns with international norms, simplifying entry into export markets. |

| Govt. Tenders | Ineligible for most government procurement or temple trust bulk orders. | Preferred Supplier: Often a mandatory requirement for bulk supply to government bodies or large institutions. |

Documents Required for Agarbatti BIS License

Before you start the application process on the Manak Online portal, ensure your paperwork is watertight. Missing documents is the #1 reason for application rejection.

Statutory & Business Documents

- Proof of Business: GST Registration Certificate, MSME/Udyam Registration, or Certificate of Incorporation.

- Premises Proof: Sale deed, Rent agreement, or Property tax receipt of the factory location.

- Identity Proof: Aadhar/PAN card of the Authorized Signatory/Director.

Technical & Manufacturing Documents

- Manufacturing Process Flowchart: A detailed diagram showing every step from bamboo splitting to dipping and packaging.

- List of Machinery: Details of mixers, extruders, dryers, and dipping vats (Make, Capacity, Quantity).

- Raw Material Specs: Test certificates for Charcoal powder, Jigat, Wood powder, Bamboo sticks, and Fragrance compounds.

- Plant Layout: A map of the factory floor highlighting production areas and storage.

Quality Control Documents

- List of Testing Equipment: Details of equipment available in your in-house lab (e.g., Burning stand, Weighing balance, Vernier caliper).

- Quality Personnel Details: Name and qualification of the Quality Control Chemist/In-charge.

- Consent Letter: If testing is outsourced to a BIS-recognized lab (though basic in-house testing capability is usually mandatory).

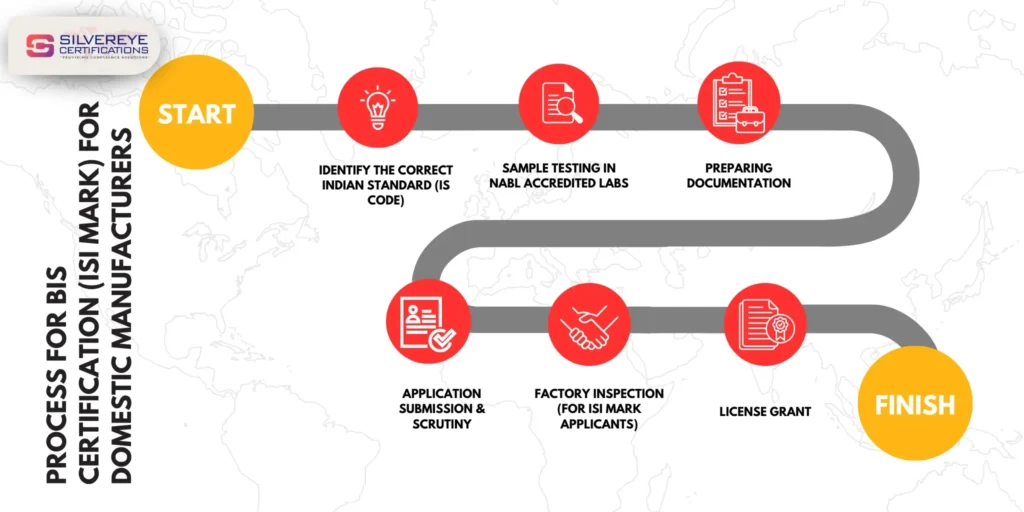

Step-by-Step Process for Grant of License

Getting the Agarbatti making certification involves a systematic procedure defined by the Bureau of Indian Standards.

Step 1: Online Application Submission

Create an account on the BIS Manak Online portal. Select the standard IS 19412:2025 and fill in the application form (Form-V). Upload all the documents listed above and pay the application fee.

Step 2: Query Resolution

BIS officials will scrutinize your application. If they find any discrepancies (e.g., mismatch in address or machinery capacity), they will raise a query. You must respond promptly to avoid delays.

Step 3: Preliminary Inspection

A BIS scientist will visit your factory physically. During this visit, they will:

- Verify the manufacturing machinery.

- Check your in-house testing capabilities.

- Witness the production process.

- Draw random samples of the finished incense sticks for independent testing.

Step 4: Sample Testing

The samples drawn during the inspection are sealed and sent to a BIS-recognized third-party laboratory or the BIS Central Lab. They will be tested for:

- Burning time and quality.

- Presence of banned chemicals (Alethrin, etc.).

- Fragrance retention.

Step 5: Grant of License (GoL)

If the lab report confirms the product meets IS 19412:2025 standards and the factory inspection was satisfactory, BIS will grant the license. You will receive a CM/L Number (Certification Marks Licence number).

Step 6: Marking & Labeling

Once you have the license, you must print the ISI Mark along with your CM/L number on every packet.

Testing, Sampling & Conformity Assessment

Mandatory Tests Prescribed Under IS 19412:2025

To get certified, your product must undergo:

- Dimensions Test: Length and thickness consistency.

- Burning Quality Test: Total burn time and ash properties.

- GC-MS Analysis: Gas Chromatography-Mass Spectrometry to screen for the banned chemicals listed above.

Sampling Procedures

BIS inspectors will not just take one packet. They follow a random sampling method from your factory lot to ensure the "Golden Sample" isn't the only good one.

Role of BIS-Recognised Laboratories

You cannot test this in-house. Samples must be sent to BIS-recognized labs (like those under CSIR or private NABL labs accredited for these specific chemical tests).

Criteria for Grant of Licence and Surveillance Audits

Once you pass the initial tests, BIS grants the license. However, they will conduct surveillance audits (surprise factory visits) to ensure you haven't switched back to cheaper, non-compliant raw materials.

BIS Standard Mark & Labelling Requirements

Eligibility to Use the BIS Standard Mark

Only manufacturers with a valid license and passing test reports can print the prestigious ISI Mark on their boxes. This mark is your biggest marketing asset.

Mandatory Labelling Information

Your packaging must now be transparent. Required details include:

- Generic Name: "Incense Sticks" or "Agarbatti."

- Type: (e.g., "Masala Agarbatti").

- Net Quantity: Weight or number of sticks.

- Batch Number & Mfg Date.

- Burning Time: (Approximate).

Additional Good Practices

It is recommended to add safety warnings like: "Use in well-ventilated spaces" or "Place on fire-proof surface."

Compliance Roadmap for Incense Stick Manufacturers

If you are a client of Silvereye Certifications, you know we believe in being proactive. Here is your action plan:

Step 1 – Internal Gap Assessment

Check your current formulation. Are you using any fragrance suppliers who cannot provide a "Free from Prohibited Substances" certificate? Audit them immediately.

Step 2 – Reformulation & Raw Material Re-Sourcing

If your "Strong Jasmine" fragrance contains Benzyl Cyanide, you need to switch to a safer, likely slightly more expensive, alternative.

Step 3 – Pilot Testing

Before applying to BIS, send a sample to a third-party lab for a "pre-test." It’s better to fail privately and fix it than to fail an official BIS test.

Step 4 – Filing for BIS Licence

Submit your application via the Manak Online portal. This involves uploading your factory layout, machinery list (mixers, extruders), and QC personnel details.

Step 5 – Ongoing Quality Control

Set up a small in-house lab to check simple parameters like stick length and burning time daily. Keep records—BIS loves paperwork.

Implications for Importers, Brand Owners & Retailers

Sourcing from BIS-Compliant Manufacturers

If you are a brand owner who outsources manufacturing (White Labeling), you are liable for the product quality. Insert a clause in your vendor contracts requiring compliance with IS 19412:2025.

Documentation Importers Should Maintain

For importers bringing in high-end incense from places like Vietnam or Japan, you must ensure they meet these Indian standards. BIS certification is increasingly becoming a non-tariff barrier to block low-quality imports.

Retailer Responsibilities

Retailers should start prioritizing stock that carries the ISI mark. If a consumer complaint arises regarding health issues, selling a BIS-certified product offers you a layer of legal protection.

Impact on Consumers, Workers & Environment

Reduced Exposure to Harmful Chemicals

For the end-user, this means the air in their temple or meditation corner is actually clean. No more headaches or eye irritation from harsh chemical smoke.

Protection of Workers

The women rolling these sticks in cottage industries are the first victims of toxic raw materials. Banning dangerous chemicals protects the workforce from skin diseases and respiratory ailments.

Environmental Benefits

Cleaner burning sticks mean less pollutant load on our environment. It aligns with the broader "Green India" mission.

Estimated Cost & Timeline for IS 19412:2025 Certification

For a manufacturer, budgeting for BIS certification is just as important as the technical setup. Below is a breakdown of the government fees, testing charges, and the time investment required.

Estimated Cost Breakdown (Per Application)

| Cost Head | Estimated Amount (INR) | Description |

| Application Fee | ₹1,000 | Non-refundable fee paid to BIS at the time of submission. |

| Audit Fee | ₹7,000 (per man-day) | Paid for the BIS officer’s visit to your factory. (Excludes travel & stay). |

| Lab Testing Charges | ₹15,000 - ₹25,000* | Paid to the lab. Varies significantly based on tests (e.g., GC-MS for banned chemicals). |

| Annual License Fee | ₹1,000 | Recurring annual fee to keep the license active. |

| Minimum Marking Fee | ₹46,000 - ₹55,000* | Advance payment. This is the minimum royalty you pay to BIS annually for using the ISI mark. |

| Consultancy Fee | Variable | Professional fees for agencies like Silvereye Certifications to handle documentation & liaison. |

Note: The "Marking Fee" is volume-based. If your production is high, you pay per unit. If production is low, you pay the Minimum Marking Fee.

Certification Timeline (Standard Procedure)

| Stage | Duration (Approx.) | Activity |

| 1. Application Filing | Day 1–5 | Submission of Form-V and uploading of factory documents on Manak Online. |

| 2. Scrutiny & Query | Day 6–15 | BIS officials review documents. Queries raised must be resolved immediately. |

| 3. Factory Audit | Day 16–30 | BIS officer visits the factory, verifies machinery, and draws samples. |

| 4. Lab Testing | Day 31–50 | Samples are tested in a third-party lab. Delays often happen here if labs are busy. |

| 5. Grant of License | Day 51–60 | If test reports are clear, the license number (CM/L) is generated. |

| Total Time | 45 – 60 Days | Can take up to 90 days if samples fail or documents are missing. |

License Validity and Renewal Process

Obtaining the license is Step 1. Keeping it is Step 2. BIS licenses are not lifetime awards; they must be renewed to ensure continuous compliance.

Validity & Renewal Terms

| Parameter | Details |

| Initial Validity | 1 Year usually granted for the first term. |

| Renewal Period | Can be renewed for 1 to 5 years at a time in subsequent cycles. |

| Renewal Window | Apply for renewal 1 month before the license expiry date to avoid penalties. |

| Late Renewal | Allowed up to 90 days after expiry with a Late Fee of ₹5,000. |

| Production Returns | You must submit monthly/quarterly production data to BIS online. |

| Stop Marking | If the license expires and is not renewed, you must immediately stop printing the ISI mark. |

How Silvereye Certifications Saves Your Time

While the official timeline is 60 days, errors in documentation can drag this out to 6 months. Silvereye Certifications pre-audits your documents and coordinates with labs to ensure your application moves through the "Green Channel," potentially cutting your waiting time by 30%.

Conclusion – Strategic Way Forward for the Incense Stick Industry

The launch of IS 19412:2025 is not a hurdle; it is a filter. It filters out the non-serious, unsafe players and highlights the quality manufacturers.

Key Takeaways:

- Audit your chemicals: Ensure no banned substances are entering your factory.

- Test early: Don't wait for the mandatory notification.

- Market the Safety: Tell your customers you are compliant.

For manufacturers, the message is clear: The era of unregulated smoke is over. The future belongs to clean, certified, and safe aromas.

Ready to get your Agarbatti business BIS certified?

Navigating BIS standards can be tricky. At Silvereye Certifications, we specialize in simplifying compliance for manufacturers like you.

Frequently Asked Questions

Is IS 19412 mandatory right now?

No, it is currently voluntary. However, the government is expected to issue a Quality Control Order (QCO) soon, making it mandatory overnight.

Can "Mosquito Repellent" sticks get this mark?

No. If it kills bugs (contains Alethrin/Transfluthrin), it needs a CIB License, not this BIS certification. IS 19412 is strictly for safe, non-toxic incense.

Which chemicals are banned?

You must remove all insecticides (Alethrin, Permethrin) and toxic intermediates like Benzyl Cyanide and Ethyl Acrylate from your fragrance.

Is the process cheaper for MSMEs?

Yes. While the testing standards are the same for everyone, the government offers subsidized marking fees for Micro and Small Enterprises.

How long does certification take?

Typically 45 to 60 days, provided your factory audit goes well and your samples pass the lab tests on the first try.

Does this cover Dhoop, Cones, or Cups?

No. This specific standard (IS 19412) is exclusively for Incense Sticks (bamboo core or masala). Other formats are not covered yet.

What happens if my sample fails the lab test?

Your application is rejected immediately, and fees are forfeited. You must fix the formula and re-apply. Always pre-test before the official audit.

Do importers need this license?

Eventually, yes. As quality norms tighten, foreign manufacturers (from Vietnam/China) will need FMCS certification to sell in the Indian market.

Will this help my export business?

Absolutely. It acts as a "Clean Label" guarantee, proving to US/EU buyers that your product is free from hidden toxins and carcinogens.

How long is the license valid?

It is granted for 1 year initially. After that, you can renew it for blocks of 1 to 5 years based on your compliance track record.